Green Zone Building Cleaning Services is a professional cleaning & maintenance company based in Dubai, United Arab Emirates, offering a complete range of cleaning solutions.

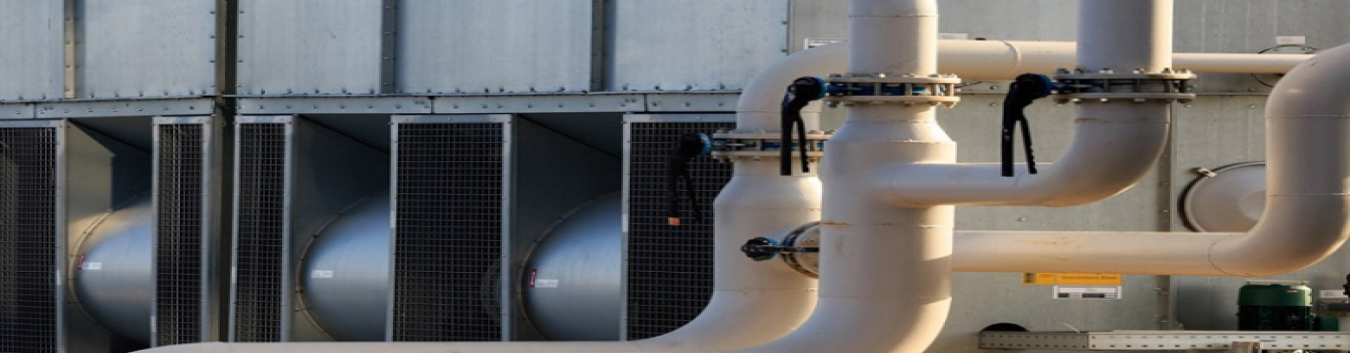

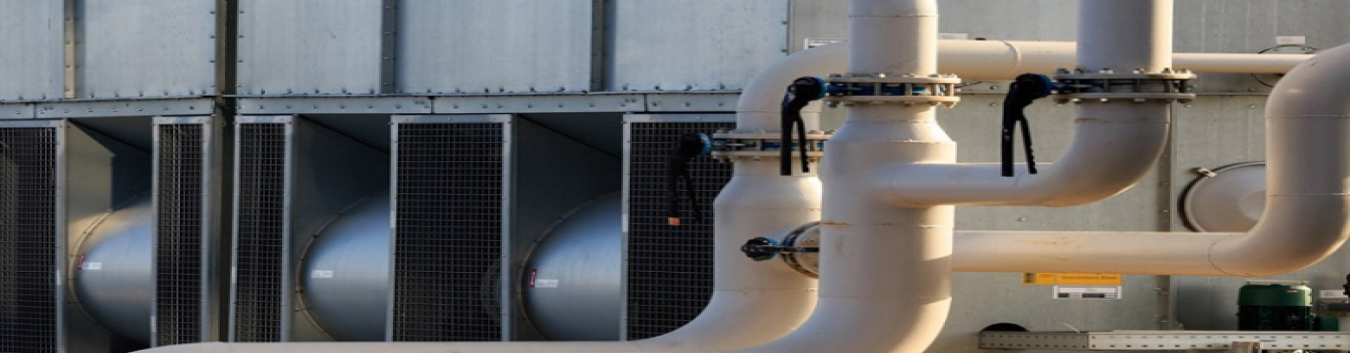

Cooling Tower Cleaning

Cooling towers provide an ideal environment for the growth and incubation of many organisms, including the Legionella bacteria. Periods of non-use (winter lay-up) exacerbate the problem. Although a consistent biocide program can reduce the risks, it is best practice to clean a cooling tower at least twice a year. We will work with you to customise a cleaning program that will meet health department guidelines and standards whilst meeting your specific needs.

How we clean your cooling tower:

Green Zone Building Cleaning Services is a professional cleaning & maintenance company based in Dubai, United Arab Emirates, offering a complete range of cleaning solutions.

Green Zone Building Cleaning Services,

Office 145 M Floor, Hamsah A Building Al Karma, Dubai UAE

: P.O Box:43646 Dubai-UAE

:+971 4824 0822

: +971 5071 30822 /+971 5048 30822

: reach@greenzone.ae

Copyright © 2025, Green Zone. All rights reserved.